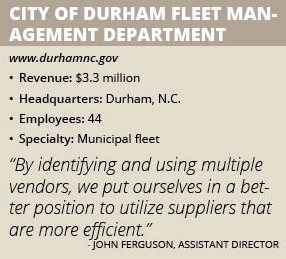

City of Durham Fleet Management Department

Durham Fleet Management Department captures a plethora of data on its equipment and vendors to ensure it remains one of the leading fleets in the country.

By Janice Hoppe-Spiers, Senior Editor at Knighthouse Publishing

The city of Durham Fleet Management Department is uniquely positioned in that it oversees only the city’s equipment and vehicles, ensuring each department receives equal treatment and service. “We manage the city’s fleet from cradle to grave,” Fleet Management Director Joe Clark says. “When fleet management falls under another department, it might be an afterthought. We are proud to play a supporting role to the city’s departments.”

Durham Fleet Management manages 1,700 vehicles, including police squad cars, fire trucks, backhoes, solid waste trucks and sewer vacuums. “We run the fleet like a business and try to achieve the greatest return on investment by looking at lifecycle cost, cost-per-mile and many service delivery metrics,” Clark says. “Many times, these decisions are viewed as unconventional or non-conforming. Our goal is to continue to be one of the leading fleets in America.”

Durham Fleet Management has been named a “Leading Fleet” the past four years by the Leading Fleets Award sponsored by the Government Fleet magazine, a “100 Best fleet” the past five years by the 100 Best Fleets Award program and a “Green Fleet” for the past five years by the Green Fleets Award Program. In October, North Carolina Mobile Care and the North Carolina Clean Energy Technology Center named Durham a 2018 Smart Fleet Champion.

The department continues to lead the way through data-driven analysis and decision-making processes in the hope of achieving prescriptive analysis and streamlined processes. “An analogous goal is to achieve a level of cooperation and partnership with our clients that develops unprecedented levels of efficiency,” Clark says. “In an effort to achieve this, Fleet Management has already begun the development of department level (micro) analysis and review of fleets and their impact on department mission.”

By handling equipment throughout its lifecycle, Durham Fleet Management starts accumulating data on each piece the moment it is delivered. “We build a birth certificate and every bit of data and miles driven are in one spot and follow it through to the end of the lifecycle,” Clark explains. “We set vehicles up by class and then we start to peel the layers off that can lead to the discover of problems with a particular brand and determine which performs better than others. A lot of times, one brand may appear to be the most cost-effective, but it isn’t the best vehicle. We take opinions out and look at the facts.”

Responsible Sourcing

Durham Fleet Management has a dedicated funding source for replacing vehicles and equipment. This year, the department will spend about $10 million replacing old equipment and prides itself on being a responsible steward of the city’s physical and environmental assets. “People sometimes go into things a little blind and they are more worried about notoriety and being a trendsetter than the process improvements or efficiencies they can gain,” Ferguson explains. “We are trendsetters if ROI indicates it’s worth the spend.

“We look for value in all the decisions we make,” he continues. “We are spending taxpayer dollars, so if we can be a trendsetter and it makes sound financial sense, we’ll revel in that notoriety and take backlash for not jumping on things because they don’t make sense. We would rather wind up with five modern fuel-efficient vehicles than two that won’t get used but are clean burning.”

Durham Fleet Management believes there is more to value than the lowest cost, which is why it constantly reviews supplier availability and performance to increase production and reduce downtime. “By identifying and using multiple vendors, we put ourselves in a better position to utilize suppliers that are more efficient,” Ferguson says. “All manufacturers have problem areas associated with vehicles, but we want to know how they deal with those problems. We look at the supply chain, discounts based on volume and service after the sale. Will they support us to reclaim any loss and help us out on the back side with replacement parts.”

By being able to better predict supply chain deliveries, Durham Fleet Management can better schedule repairs to decrease downtime for its customers, which are the city’s departments. The department reviews its dealers to determine which ones have state contract agreements or national accounts to piggyback on those to guarantee basement prices. “We challenge our inventory personnel to call shops and depending on the dollar amount, they have to provide at least two quotes, so they are constantly cost shopping,” Ferguson notes. “Our vendors know we are doing that.”

Durham Fleet Management says constant communication is a two-way street with its suppliers and developing good relationships is key. “We pay our bills on time and they supply the part, and at the end of the day, we are even,” Ferguson says. “We can’t do it without those folks, so we let them know we appreciate and value the relationship. It’s important for vendors to know it’s a two-way street and when it gets one sided for us or them, that is when something has to give and we know we aren’t going to be successful.”

The department also leans on its suppliers to conduct product knowledge training to its procurement team. This knowledge allows for better decision-making as it pertains to time versus cost analysis. TranSource Truck & Trailer, for example, is one of its suppliers that will host training classes on emissions and assist its technicians when needed.

Durham Fleet Management also reaches out to its suppliers to gain insight on software needs and product development changes. “If you don’t ask, they won’t call and tell you,” Ferguson notes. “We ask them what’s coming over the horizon and what they see in the future. We are in communication monthly with our suppliers.”

Moving forward, Durham Fleet Management sees more emission and fuel efficiency requirements in the future, which will require manufacturers to get creative and for the department to be on the front of the learning curve. “We make sure we have a voice with our suppliers so we can communicate our struggles and expectations,” Ferguson says. “Selling us the vehicle is the easy part. It’s the support afterwards and helping us maintain it to keep that vehicle on the road.”