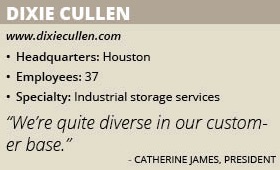

Dixie Cullen: Leading the Way in Industrial Storage Excellence

Deckhead: Dixie Cullen prepares to expand its capabilities with a new facility at the Port of Houston.

By Alan Dorich, Senior Editor at Knighthouse Media

When ExxonMobil or Chevron need reliable storage solutions, they turn to Dixie Cullen. “We pay attention to the small details,” President Catherine James says, the company’s high level of service has earned it a strong referral rate. “Our customers bring us new customers.”

James founded the Houston-based company nearly 25 years ago while working for another firm that had a client who needed storage services. The company was not able to provide them, but it gave her the idea to start her own firm after learning from a truck driver about an available building.

“It all came together,” James recalls. “The first location was at the corner of Dixie and Cullen right here in Houston — hence the company name.” We now have 3 warehouse locations in Houston, all with heavy lift capacity and close proximity to the Port of Houston.

Today, Dixie Cullen offers standard inside storage, climate-controlled storage, Foreign Trade Zone storage and outside storage service to its clients, which also include Shell, General Electric, Mitsubishi and Siemens. It’s not just the big Corporations, but a lot of small companies need our services too. “We’re quite diverse in our customer base,” James says.

This has put Dixie Cullen in a position where no single customer has more than 10 percent of its business, and has allowed it to survive the ups and downs in the economy. “Right now, we’re doing great,” she says. “One thing we’ve noticed is as long as the economy is going up or down and not flat, we’re doing well.”

The company also has established a strong niche in its industry by offering services that its competition does not, including climate-controlled and Foreign Trade Zone storage. “We also allow their clients service techs to come in to do preventative maintenance on their equipment. If they need heat or nitrogen put on their units, we can help them with that too,” she says.

Dixie Cullen will assist its clients in these efforts, and also features heavy overhead lifts in its facilities, which allows it to serve more clients who bring in equipment, steel and other industrial material. “We have 24 by 24 overhead doors that allow us to get the larger equipment into the building, while still on the trailer, right under the two 100-ton overhead cranes,” she adds.

Dixie Cullen also has been recognized for its work, which has included being named on the Houston Business Journal’s Fast 100 list for five years in a row. “We’re looking at this being our sixth year,” James says, noting that this has been very gratifying for the firm and to the people who have worked so hard to get us where we are today.

“We’re one of the few companies that have made that list many times,” she says, adding that the list features companies in seven counties. “Sometimes, we’ve just squeezed in there, but we’ve also made the top 10.”

The Resting Place

For the past six years, Dixie Cullen has been in an upward growth mode, which includes a recent agreement to build a 300,000-square-foot facility on the Port of Houston’s property. “[It] puts us in a great location for receiving some of the heavier equipment coming through the port,” James says.

This will allow Dixie Cullen to better service its clients, including one that was just brought in a 525,000-pound piece of equipment. Currently, she says, the company has to store it outside while it undergoes a permitting process, which can last four to 12 weeks.

But that will change when Dixie Cullen’s new facility fully opens. “Our customers want it in this secured facility, where there are cameras and it’s fenced in,” she says. “We’ll be the safe resting place for them.”

The facility also will future enough yard space to allow the transfer of equipment. Currently, “We have a small 30,000 square foot newly rebuilt building on site already in operation,” she says, noting that the rest of the facility will be open in the next 18 months.

Urgent Business

Dixie Cullen continues to adjust to an evolving market, including changes in customers’ expectations. “They want everything right away,” James describes. “So we’re seeing a lot of urgency in the market right now.”

The company also has coped with clients trying to move ahead of the market and bring products to the United States before their competitors. “They figure if this product is only available overseas and they’ve got it in a warehouse in Houston, they have a four- to six-week advantage to sell it in the United States,” she explains.

Its clients also are using Dixie Cullen’s services while they performing upgrades and expansions at their own locations. “They can’t take the equipment at their facility until they completely retrofit what they’re doing,” she says.

According to James, insurance companies also have become stricter, preventing clients from leaving their equipment in the field and making Dixie Cullen’s services a viable option. “We’re seeing a lot more new equipment coming through that is project related,” she says.

Strong Support

James is proud of Dixie Cullen, which is preparing to celebrate 25 years this November. “I never thought that would happen,” she admits. “We went through some rough patches and hung in there.”

She credits this to the strong support of her team. “We could not have done it without our employees,” she asserts, noting that this includes her sister, Elizabeth, who is the company’s CFO. “Without everyone pulling together, we wouldn’t be where we are today.”

Many have been at her side at the company since day one despite the challenges of the business. “It can be crazy depending on how many trucks are waiting out there, but it’s a friendly environment,” she asserts, noting that it can be difficult to find new associates.

Much of the difficulty lies in being able to understand the work ethic that Dixie Cullen has nurtured. “Others don’t realize the mistakes that they made in the past follow them,” she says. “When you’re doing FTZ and international business, you’ve got to do background checks.”

These previous mistakes, James explains, follow them through life can prevent people from getting roles at the company. “They don’t realize what they’re doing could cost them future jobs,” she says. “I joke that they need to decide in kindergarten if they’re going to stay out of trouble.”

Happy in Houston

James sees a strong future ahead for Dixie Cullen, as it currently stands as a leader in its industry. One aspect that has put it in that position is that it is “more forward thinking than a lot of our competition into what the future is holding for us,” she says.

Keeping the communication lines open with our customers is so very important to knowing what potential space and equipment requirements we have coming up and planning for those possibilities so that everything is seamless. In planning we have opted for the heavy lift overhead cranes, but also have included mobile cranes for the yard. A 200-ton mobile crane at our Market Street facility and a 175-ton mobile crane at our Mississippi Street facility.

“We’re planning ahead,” she continues, noting that Dixie Cullen has had other companies approach it about opening warehouses in their regions. “We have customers that have begged us to open in their cities.”

But James does not plan to expand its reach any time soon. “We’re happy here in Houston,” she says. “We plan on staying here for quite a while.”

Strong Savings

Dixie Cullen operates warehouse facilities with more than 530,000 square feet that are designed to service the industrial storage needs for machinery, steel, equipment, product and material. “Trucks arriving and departing our facilities, with the use of our heavy-duty overhead cranes, are expedited upon their arrival providing substantial savings to our customers.”

According to the company, this has made machinery dealers, manufacturers, importers and brokers feel as though Dixie Cullen is an extension of their own operations. “Our fenced-in, secure yards permit customers to use our facilities for outside storage of equipment, construction equipment and containers that they do not require to be stored inside,” it says.

Dixie Cullen also is in close proximity to the Port of Houston, which has allowed it to set up distribution for international firms that ship their material in by container loads. Having the company pull, store and reship in smaller lots allows it to save time and expense “for everyone involved,” the company says.