Shell Commercial Fuels

The road to the new normal

Making consumables work for your bottom line

Shell and Automotive Testing Papenburg (ATP) demonstrate Total Cost of Ownership savings from Shell premium fuel and lubricants tested in real-world conditions. Results from the  successful collaboration include 8.9 per cent fuel economy1 as a combined efficiency benefit and 5.28 per cent more load-pulling power1 from cleaned-up fuel injectors.

successful collaboration include 8.9 per cent fuel economy1 as a combined efficiency benefit and 5.28 per cent more load-pulling power1 from cleaned-up fuel injectors.

Navigating your fleet through a dynamic industry environment is a difficult job at the best of times, but with the impact of COVID-19 resulting in further cost pressures and tighter margins, there is a much greater task on fleet managers to unlock efficiencies wherever possible. Increasing your output by using fewer resources may seem like a conflicting equation, but valuable bottom line gains can be achieved by going back to basics and focusing on the variables that are in your control, such as your consumables. The fuel and lubricant you select can have a big impact on fleet efficiency and success, making it crucial that you maximize the value that consumables provide to your company.

To show this value, professional experts put consumables to the test under real-world conditions. Shell recently collaborated with Automotive Testing Papenburg (ATP) to do just that, measuring the Total Cost of Ownership (TCO) savings that can be achieved when using Shell premium fuel and lubricants together. Situated in north-western Germany, ATP is known as one of the world’s most modern testing facilities for both passenger and commercial vehicles, housing more than 75 kilometres of test track. Engaging a facility at the standard of ATP allows precise testing and close monitoring of the test conditions. “It’s very important to test every time with similar conditions,” explains Ann-Cathrin Bischoff, Project Manager at ATP. “This means we have to guarantee that the driver influence is as low as possible. Therefore, we are using our driver guidance system to make sure the driver keeps the right velocity. We are also simulating some city traffic, which means velocities between zero and 50 kilometres per hour and different accelerations and decelerations.”

Over 17 days and more than 4000 kilometres, the ATP engineering team took to the track in heavy-duty vehicles to test Shell FuelSave Diesel – the latest generation of Shell diesel with DYNAFLEX Technology – alongside two of Shell’s leading heavy-duty lubricants, Shell Rimula and Shell Spirax, against regular diesel and standard lubricants. The result was a real-world measurement of how the tested products impact the overall performance of the engine.

While there is a growing awareness across the on-highway sector of the benefits that either a premium fuel or a premium lubricant can have on fleet performance, the ATP test demonstrates the additional efficiencies that can be unlocked by combining the two. “Using Shell premium products, I especially noted that we were able to reduce fuel consumption,  lower costs and additionally have a beneficial impact on the environment,” explains Markus Bloem, Project Manager, Heavy Duty Vehicle Testing at ATP. And indeed, testing showed that when used together, Shell FuelSave Diesel and premium Shell lubricants can deliver up to 8.9 per cent fuel economy2, a figure that could have significant cost saving potential when viewed in light of the 23 per cent share of total operating costs that fuel tends to account for3.

lower costs and additionally have a beneficial impact on the environment,” explains Markus Bloem, Project Manager, Heavy Duty Vehicle Testing at ATP. And indeed, testing showed that when used together, Shell FuelSave Diesel and premium Shell lubricants can deliver up to 8.9 per cent fuel economy2, a figure that could have significant cost saving potential when viewed in light of the 23 per cent share of total operating costs that fuel tends to account for3.

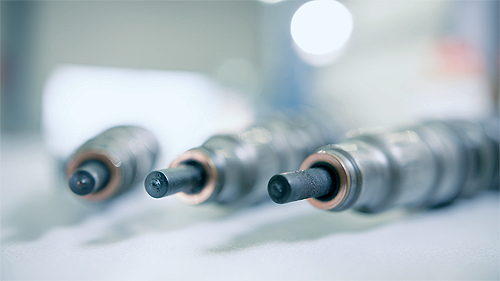

The results also highlight the increased productivity that Shell FuelSave Diesel can offer, with ATP measuring up to 5.28 per cent more load-pulling power when compared with regular diesel2. The ability to maintain engine efficiency while accelerating with heavy loads or on steep terrain is vital for any fleets that are consistently operating at a high capacity or running to tight schedules. A key success factor here is the health of your injection system, particularly injector cleanliness. To evaluate the conditions of injectors during the test, a fibreoptic camera was used to inspect the inner workings of the engine, checking for carbon deposits and assessing overall cleanliness of components. Shell and ATP found that Shell FuelSave Diesel was able to clean up such deposits and thus achieve more load-pulling power and better fuel economy in city and urban driving conditions2.

Being able to rely on products with performance proven under real-life conditions and by independent test experts such as ATP will be key to ramping up operations as industries become more accustomed to the impact of the pandemic, since the efficiency gains that once offered a competitive edge, may now be essential for survival. As the ATP testing shows, the right consumable selection can greatly increase the efficiency of your heavy-duty engines, providing you with an opportunity to deliver higher output with fewer resources when this is arguably needed most. It also shows that there could be even greater improvements awaiting you when premium fuel and lubricants are used in tandem. So, while ensuring your  business stays on track amidst competing priorities, do not lose sight of what is fuelling your journey and how it can benefit your bottom line.

business stays on track amidst competing priorities, do not lose sight of what is fuelling your journey and how it can benefit your bottom line.

1 – Compared to regular diesel without fuel economy formula and to standard lubricant. Based on demonstration tests with heavy duty EU VI trucks in real-life city and urban conditions in collaboration with ATP, Germany. Customer benefits will vary according to type of operation, vehicle, driving conditions and driving style.

2 – Shell, “On-Road Testing of Shell Differentiated Fuels and Lubricants.” Shell YouTube. July 29, 2020. (accessed September 22, 2020).

3 – Shell Commercial Fuels (2018). Making Fuel Work for your Bottom Line: Overcoming the false economy that standard fuels can help the road transport sector reduce Total Cost of Ownership (page 3). London, Edelman.

For more information, you can:

• Visit the Shell website here

• Find out more on Shell FuelSave Diesel and Shell Diesel Extra here

• Watch a video on the testing and results here

• Contact a local Shell representative here